Polycarbonate

PC is a versatile, robust, and heat-resistant material ideal for crafting your complex designs. With its excellent durability, toughness and rigidity, it's perfect for a wide range of applications. Experience the future of 3D printing with Polycarbonate at Weerg.

PROS

- Durability

- Toughness

- Rigidity

- High layer adhesion - almost isotropic

CONS

- UV sensitive

- Printed with breakaway supports

- Black finish sensitive to fingerprints

MAIN FEATURES

- 3D Printing process: FDM

- Tolerances: < 100mm ± 0,60mm; > 100mm ± 0,75%

- Max size: 250 x 250 x 250 mm; 9,8 x 9,8 x 9,8 in

- Lead time: <3 days

POLYCARBONATE 3D PRINTED VIDEO GALLERY

Durability

Choose this material for strong and durable 3D printing projects that can withstand heavy impacts and stress while maintaining their shape and form over time. Ideal for tough applications.

Layer Adhesion

It exceptional layer adhesion allows designers to exploit the FDM printing technology in ways not possible with other materials and technologies. 3D printed PC behaves much closer to an isotropic material and it is strong also along the Z direction.

Mechanical properties

It is a remarkably tough material but despite this, it is also quite rigid. This mix of properties makes it ideal for printing functional components in a wide variety of applications, making it an incredibly versatile material.

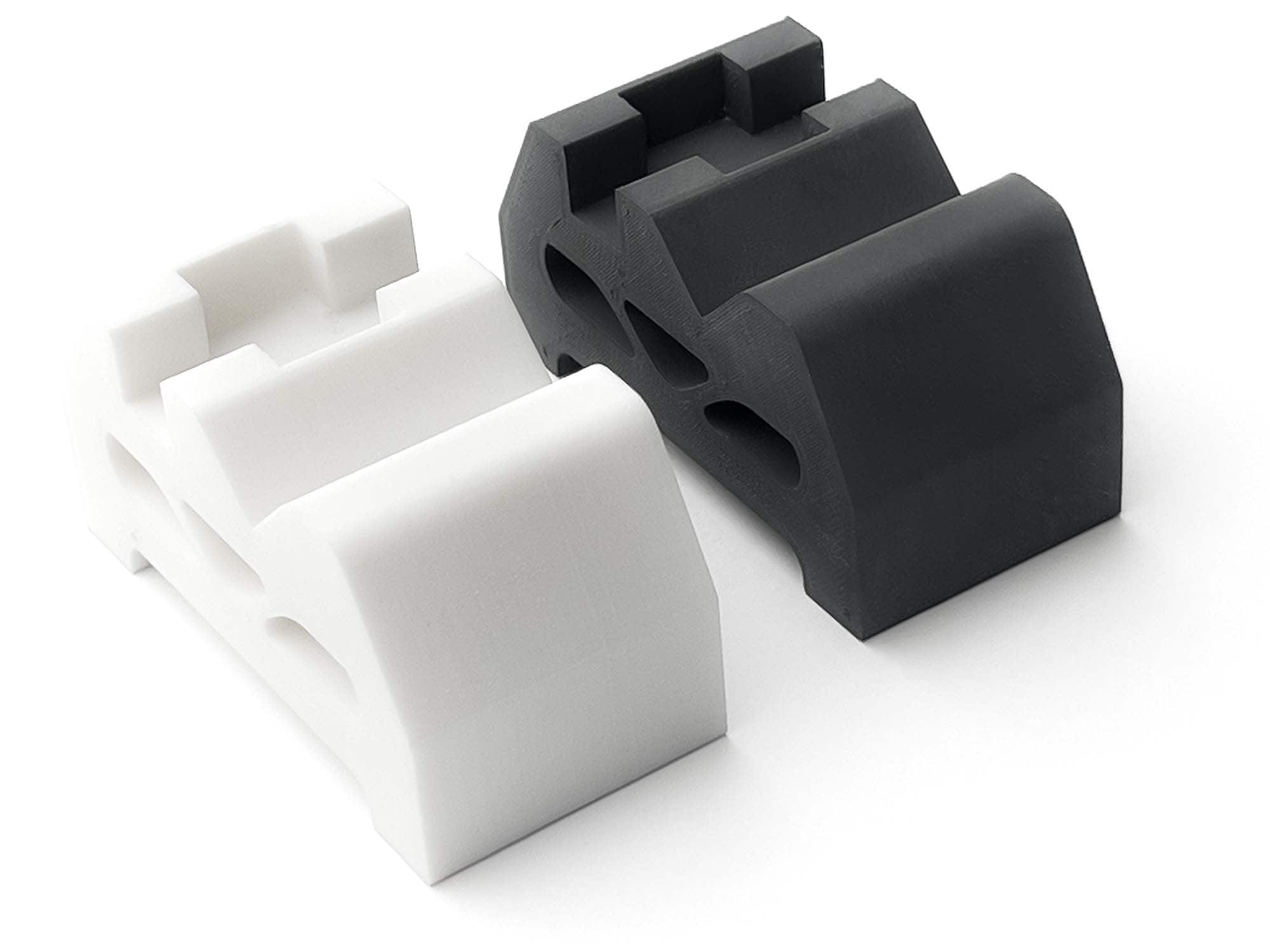

POLYCARBONATE IMAGE GALLERY

QUOTE NOW YOUR PARTS

free instant quoteCOMMENT

Polycarbonate (PC) is a dynamic and high-performance material that stands out in the 3D printing landscape. This material brings forth a striking combination of remarkable properties including superior durability, high heat resistance, and impressive flexibility.

Pros

• Unrivalled Durability

For 3D printing projects that demand strength and durability, look no further than polycarbonate. This material can withstand heavy impacts and stress while retaining its shape and form over time, making it the perfect choice for tough applications.

• Layer Adhesion

Thanks to its exceptional layer adhesion, it is a game-changer in 3D printing technology. This material allows for designs that were not previously possible with other materials. Additionally, printed PC behaves much closer to an isotropic material, resulting in strength along the Z direction.

• Mechanical properties

With its impressive toughness and rigidity, it is the perfect material for creating functional components across a wide range of applications. Its versatility knows no bounds, making it an exceptional choice for any project that demands strength and reliability.

Cons

• Printed with breakaway supports

The printed component needs to allow the operator to have access to all supports to mechanically remove the support structures. PC may not be the best suited for very intricate geometry or features with low spacing.

• Black finish sensitive to fingerprints

All components have a distinct and uniform matte finish but the black components tend to be sensitive to fingerprints that can be noticeable on the surface.

Comparison to other plastics:

When we compare PC to other plastics used in 3D printing, the distinct characteristics and superior properties of this material become more evident.

PLA (Polylactic Acid):

PLA is a common material used in 3D printing, known for its ease of printing and environmentally friendly attributes as it's derived from renewable resources like corn starch or sugar cane. However, when it comes to mechanical and thermal properties, Polycarbonate takes the lead. While PLA offers great printability, it falls short in terms of impact resistance and heat deflection, areas where Polycarbonate excels. Furthermore, PC outperforms PLA in terms of overall mechanical properties, making it a more suitable option for parts requiring a degree of bend without breaking.

ABS (Acrylonitrile Butadiene Styrene):

ABS is another widely used 3D printing material, offering good impact resistance and durability. However, the strength, heat resistance, and toughness of PC exceed those of ABS. Polycarbonate superior heat deflection temperature means it can handle high-temperature applications where ABS might deform.

Nylon (Polyamide):

Nylon is recognized for its strength and flexibility, which are comparable to PC. However, Polycarbonate pulls ahead in rigidity and isotropicity of the printed parts. Nylon tends to absorb moisture from the air, which can affect its strength and dimensional stability. In contrast, PC exhibits lower moisture absorption, providing better dimensional stability.

PETG (Polyethylene Terephthalate Glycol):

PETG combines the ease of printing of PLA and the strength of ABS. Still, PC overall performance surpasses it. While PETG offers decent durability, heat resistance, and flexibility, Polycarbonate offers these attributes to a higher degree. PC higher impact resistance and heat deflection temperature make it a more robust material for demanding applications.

In conclusion, while each plastic material has its strengths and suitable applications, PC exceptional durability, toughness, and rigidity make it stand out. It's a preferred choice for applications that require a combination of these properties.

Best applications:

Its superior durability, toughness and rigidity make it a versatile choice for a wide range of applications in different industries. Its impressive performance under challenging conditions translates to high-value usage across numerous fields.

Mechanical Components:

The high impact resistance and strength make it an excellent choice for producing sturdy mechanical parts. These might include gears, fasteners, and other moving parts within machinery where durability under repetitive stress is crucial.

Automotive Applications:

In the automotive industry, it can be used to produce parts that require high heat resistance and impact strength. These might include light housings, fender flares, bumpers, and other components that need to withstand the heat and stresses common in a vehicle's operation.

Protective Gear:

PC toughness and flexibility make it an excellent choice for protective gear such as helmets, visors, or shields.

Electronics Housings:

It is ideal for electronic housings due to its good electrical insulating properties, durability, and heat resistance. It can protect the delicate internal components while enduring the heat generated by those electronics.

Medical Devices:

In the medical field, it is used for durable components such as surgical instruments, drug delivery devices, and diagnostic equipment. Its ability to be sterilized without losing its properties makes it valuable in this industry.

Architectural and Construction Applications:

It can be used for constructing structural components like windows, skylights, or partitions. Its strength makes it a good choice for these applications.

In conclusion, the excellent mechanical, thermal, and optical properties of PC make it an adaptable and valuable material across various industries and applications. Its ability to withstand demanding conditions while maintaining its properties ensures that Polycarbonate will continue to find new and innovative uses in the world of 3D printing.

"5 Stars! Received my first Polycarbonate parts from Weerg and I'm blown away! The strength, heat resistance, and flexibility are unparalleled. Weerg precision and fast turnaround time have made all the difference. I'm excited to bring my designs to life with this incredible material. It is a game-changer!"

PROPERTIES

| Tensile breaking load | 59,7 MPa |

| Modulus of elasticity | 2048 MPa |

| Elongation at break | 12 % |

| Flexural modulus | 2044 MPa |

| HDT 0.45 MPa | 114°C |

| Izod impact resistance | 9,17 kJ/m² |

QUOTE IN 1 SECOND WITHOUT COMMITMENT

DON'T WAIT: UPLOAD YOUR 3D FILE AND GET A QUOTE FOR YOUR PARTS NOW!

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote