ASA

The Go-To UV-Resistant, All-Weather Material for Long-Lasting 3D Printed Parts. Ideal for Outdoor Applications with Superior Mechanical Properties and High Impact Resistance.

PROS

- UV Resistance

- Mechanical Durability

- All-Weather Performance

CONS

- Finish Quality

- Limited Chemical Resistance

- Limited Temperature Resistance

MAIN FEATURES

- 3D Printing process: FDM

- Tolerances: ± 0,60mm < 100mm; ± 0,75% > 100mm

- Max size: 250 x 250 x 250 mm; 9,8 x 9,8 x 9,8 in

- Lead time: <3 days

ASA 3D printed VIDEO GALLERY

UV Resistance

ASA is a top choice for outdoor applications due to its superior UV resistance. Unlike other materials that can yellow and weaken when exposed to sunlight over time, ASA maintains both its color and structural integrity, making it long-lasting and reliable for outdoor use.

Mechanical Durability

ASA stands out for its remarkable mechanical durability, including excellent impact resistance. This makes it a reliable choice for applications that demand structural strength and longevity, providing confidence in the ability of the material to withstand physical stresses over time.

All-Weather Performance

ASA is designed to perform in extreme climatic conditions in a unique way. Whether it is extremely hot, freezing cold or heavy rain, this material retains its structural integrity and appearance. Its resistance to temperature fluctuations and weather conditions makes it an ideal choice for outdoor applications requiring long-term stability.

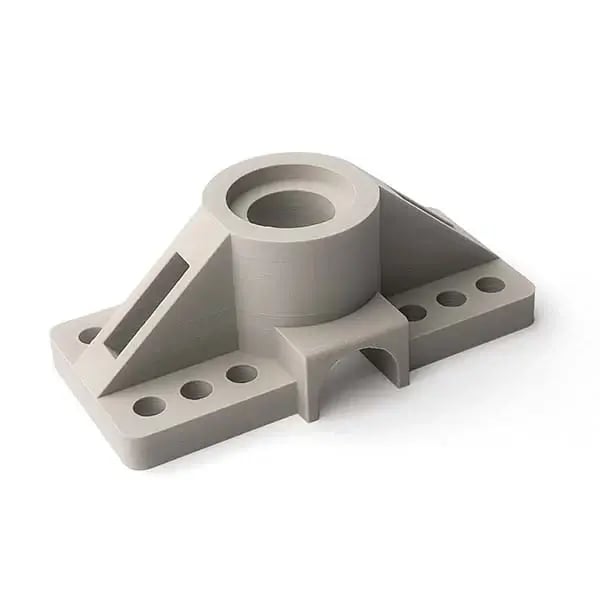

IMAGE GALLERY

QUOTE NOW YOUR PARTS

free instant quoteCOMMENT

ASA is a thermoplastic polymer known for its strong resilience against ultraviolet (UV) radiation, weathering, and thermal exposure. Derived from acrylonitrile, styrene, and acrylate, this material offers a balanced combination of mechanical and thermal properties, making it a versatile choice for various industrial applications. Its performance characteristics place it in a unique position as an alternative to more traditional materials like ABS and PLA, especially when the application demands more robust environmental stability.

Pros

• UV resistance

One of the standout features of ASA is its exceptional UV resistance. Unlike traditional materials like ABS or PLA, ASA retains its color and mechanical properties when exposed to the elements. This characteristic makes it an ideal choice for outdoor applications, including automotive exteriors and garden equipment.

• Mechanical Durability

ASA is renowned for its mechanical strength and significantly beats standard materials such as PETG or PLA in numerous applications. With impressive tensile and compressive strength, it is designed to withstand high levels of mechanical stress over long periods. This makes it an excellent choice for parts requiring durable strength, such as gears, fasteners or mounting brackets. The high levels of mechanical durability also extend its use in outdoor environments and in machinery that must withstand harsh or abrasive environments. Thanks to these exceptional mechanical properties, ASA is increasingly popular in sectors such as automotive, aerospace and industrial machinery as a reliable material for a wide range of high-stress applications.

• All-Weather Performance

ASA excels in offering consistent performance under a variety of weather conditions. Unlike materials like PLA or ABS, which can warp or degrade when exposed to the elements, ASA maintains its physical and aesthetic properties even under prolonged sun exposure, rain, or temperature fluctuations. Its inherent resistance to UV radiation makes it a preferred choice for outdoor applications, as it won't yellow or become brittle over time. Additionally, its excellent moisture resistance ensures that it won't swell or lose its dimensional stability, a critical factor for parts that must maintain their form and function in all seasons. Whether in hot and sunny climates or in cold and humid environments, the all-weather performance of ASA makes it a versatile material, suitable for all kinds of applications, from outdoor signage to automotive components, which have to withstand variable and often difficult conditions.

Cons

• Finish Quality

In 3D printing, ASA finish isn't as smooth as PLA or ABS. Visible layer lines and extra post-processing steps are often needed, adding to the time and cost.

• Limited Chemical Resistance

While ASA is more chemically resistant than PLA, it may not be suitable for applications where exposure to harsh chemicals or solvents is a concern. It can degrade or become brittle when exposed to certain chemicals, so it's important to consider the specific chemical environment when choosing ASA for a project. In such cases, materials like ABS or Nylon might be better suited.

• Limited Temperature Resistance

ASA has good resistance to UV radiation and weathering, making it suitable for outdoor applications. However, it has a lower heat resistance compared to some other 3D printing materials like ABS or Polycarbonate. ASA starts to soften at relatively low temperatures, typically around 80-90°C (176-194°F). This limitation can restrict its use in applications where exposure to high temperatures is a concern.

Comparison to other common materials

ABS (Acrylonitrile Butadiene Styrene)

Similarities: Like ASA, ABS also has good mechanical properties and is easy to work with.

Differences: ABS tends to have lower UV and weather resistance compared to ASA, making ASA more suitable for outdoor applications.

PEEK (Polyether Ether Ketone)

Similarities: Both materials offer high mechanical strength.

Differences: PEEK stands out for its extreme temperature resistance and chemical inertia. However, it is much more expensive and harder to process compared to ASA.

Nylon PA12

Similarities: Both ASA and PA12 offer good mechanical durability.

Differences: PA12 is more flexible and better suited for parts that need to withstand wear and tear, but it lacks ASA UV resistance.

PLA (Polylactic Acid)

Similarities: Both are popular for 3D printing due to their ease of use.

Differences: PLA is biodegradable and offers a smoother finish but lacks the mechanical strength and UV resistance of ASA.

PETG (Polyethylene Terephthalate Glycol)

Similarities: Both are good for mechanical parts and offer some degree of weather resistance.

Differences: generally not as UV resistant as ASA.

In summary, ASA offers a balanced profile, being strong, durable, and UV-resistant, making it a suitable choice for a wide variety of applications, both indoor and outdoor. However, it may require post-processing to achieve the desired finish quality.

Conclusions

ASA is a compelling choice for those who are looking for a material that balances mechanical strength, environmental resilience, and affordability. While it may not excel in every specific attribute when compared to specialized materials like PEEK thermal resistance or Nylon PA12 flexibility, it delivers a well-rounded performance profile suitable for a diverse range of applications. Specifically, its UV and weather resistance make it a particularly strong candidate for outdoor applications, where many other materials fall short. However, it's essential to acknowledge its limitations, such as the need for post-processing if a high-quality finish is desired. Given its moderate cost and easier processing requirements, ASA offers a blend of features that make it a pragmatic choice for both specialized and general-purpose projects. By choosing ASA, you'll be opting for a material that doesn't compromise significantly on any front, thereby offering good value for your investment.

"Working with Weerg for our ASA 3D printed components was a game-changer. The material met all our requirements for durability and weather resistance. Weerg's expert advice and efficient service made the process seamless. Highly recommended for any professional looking for quality and reliability."

PROPERTIES

| Tensile breaking load | 49 MPa |

| Modulus of elasticity | 2200 MPa |

| Elongation at break | 20 % |

| Flexural modulus | 2300 MPa |

| HDT 0.45 MPa | 96°C |

| Izod impact resistance | 44 kJ/m² |

QUOTE IN 1 SECOND WITHOUT COMMITMENT

DON'T WAIT: UPLOAD YOUR 3D FILE AND GET A QUOTE FOR YOUR PARTS NOW!

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote